Male Branch Tee

Most Eminent Male Branch Tee Pipe Fitting Manufacturer, Male Branch Tee Instrumentation Pipe Fitting, Male Branch Tee Connector, Male Branch Tee Stockist, Male Branch Tee Adapter, Male Branch Tee Tubing, Male Branch Tee with Ferrule Fittings Supplier

Stainless Steel Male Branch Tee Fittings Stockist, Carbon Steel Male Branch Tee Pipe Fittings, Nickel Alloy Male Branch Tee Fittings, Alloy Steel Male Branch Tee Pipes Fittings Exporter

Another predominant sort of pipe fitting is a male branch tee. The basic qualification between the male and male branch tee is that while the male branch tee connects with a male NPT string, the Male Branch Tee partners fractional chambers to male NPT strings. These sorts of fittings come in inch and metric size tubing and are commonly used in different ventures. Materials used are-Tempered steel, metal, bronze, carbon steel, cast iron, amalgam, copper, elastic, plastic, etc.

Our in-house age of Male Branch Tee is made with astounding nature of crude materials to suit the fixing work generally in electrical undertakings and forced air system organizations. These consequences of our own have been particularly mentioned and broadly used by the clients of grouped needs in different sizes. These Male Branch Tees have part amounts of different sorts to browse.

Shree Mahavir Steel Mart is a famous maker of male branch tee. We have a group of experienced and proficient workers that deal with the assembling of these items. The items fabricated by us are requested a ton and have gotten great reviews. Contact Us today to get a free estimation.

SS 304/304L Male Branch Tee Fittings, Inconel 600/601/625 Male Branch Tee Fittings, Hastelloy C22/C276 Male Branch Tee Fittings, SS 310/310S Male Branch Tee Pipe Fittings, Stainless Steel 316/316S Male Branch Tee Fittings, SS 904L Male Branch Tee Fittings

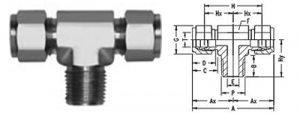

Technical Specification for Male Branch Tee

| Part no. | Equivalent Part no. Type 1 | Equivalent part no Type 2 | NPT FEMALE PIPE SIZE P | LX | ODT-ØT(INCHES) | Ø E | BODY HEX F | C | NUT HEX W | D | L1 |

| 2-MBTD-2N | -200 – 3 – 2TTM | 2MBT2N | 1/8 | 0.70 | 1/8 | 0.09 | 9/16 | 0.60 | 7/16 | 0.50 | 1.86 |

| 2-MBTD-4N | -200 – 3 – 4TTM | 2MBT4N | 1/4 | 0.92 | 1/8 | 0.09 | 9/16 | 0.60 | 7/16 | 0.50 | 1.94 |

| 3-MBTD-2N | -300 – 3 – 2TTM | 3MBT2N | 1/8 | 0.70 | 3/16 | 0.12 | 9/16 | 0.63 | 7/16 | 0.54 | 1.92 |

| 4-MBTD-2N | -400 – 3 – 2TTM | 4MBT2N | 1/8 | 0.74 | 1/4 | 0.19 | 9/16 | 0.70 | 9/16 | 0.60 | 2.12 |

| 4-MBTD-4N | -400 – 3 – 4TTM | 4MBT4N | 1/4 | 0.92 | 1/4 | 0.19 | 9/16 | 0.70 | 9/16 | 0.60 | 2.12 |

| 5-MBTD-2N | -500 – 3 – 2TTM | 5MBT2N | 1/8 | 0.82 | 5/16 | 0.19 | 9/16 | 0.73 | 5/8 | 0.64 | 2.34 |

| 5-MBTD-4N | -500 – 3 – 4TTM | 5MBT4N | 1/4 | 1.01 | 5/16 | 0.19 | 9/16 | 0.73 | 5/8 | 0.64 | 2.34 |

| 6-MBTD-4N | -600 – 3 – 4TTM | 6MBT4N | 1/4 | 1.00 | 3/8 | 0.28 | 13/16 | 0.86 | 11/16 | 0.66 | 2.40 |

| 6-MBTD-6N | -600 – 3 – 6TTM | 6MBT6N | 3/8 | 1.11 | 3/8 | 0.28 | 13/16 | 0.76 | 11/16 | 0.66 | 2.62 |

| 8-MBTD-6N | -810 – 3 – 8TTM | 8MBT6N | 3/8 | 1.11 | 1/2 | 0.38 | 13/16 | 0.86 | 7/8 | 0.90 | 2.84 |

| 8-MBTD-8N | -810 – 3 – 8TTM | 8MBT8N | 1/2 | 1.30 | 1/2 | 0.41 | 13/16 | 0.86 | 7/8 | 0.90 | 2.84 |

| 10-MBTD-8N | -1010 – 3 – 8TTM | 10MBT8N | 1/2 | 1.41 | 5/8 | 0.47 | 1 | 0.86 | 1 | 0.96 | 3.06 |

| 12-MBTD-12N | -1210 – 3 – 12TTM | 12MBT12N | 3/4 | 1.45 | 3/4 | 0.62 | 1-1/16 | 0.86 | 1-1/8 | 0.96 | 3.14 |

| 14-MBTD-12N | -1410 – 3 – 12TTM | 14MBT12N | 3/4 | 1.50 | 7/8 | 0.62 | 1-3/8 | 0.86 | 1-1/4- | 1.02 | 3.52 |

| 16-MBTD-12N | -1610 – 3 -12TTM | 16MBT12N | 3/4 | 1.66 | 1 | 0.62 | 1-3/8 | 1.04 | 1-1/2 | 1.23 | 3.88 |

| 16-MBTD-16N | -1610 – 3 -16TTM | 16MBT16N | 1 | 1.84 | 1 | 0.88 | 1-3/8 | 1.04- | 1-1/2 | 1.23 | 3.88 |

Material of Construction

| Monel | Monel 400, Monel K500, Monel R-405 |

| Nickel | Nickel 200, Nickel 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 718 |

| Incoloy | Incoloy 800, Inconel 800H, 800HT |

| Hastalloy | Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X |

| Titanium | Gr1, Gr2, Gr3, Gr5, Gr7, Gr11 |

| Stainless Steel | ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Carbon Steel | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

| Duplex Steel | ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61 |

| Alloy Steel | ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19 |

Dimensions of Male Branch Tee

|

|

||||||||||||||||||

| Imperial Tubing | |||||||||||||||||||

| Tube O.D inch | NPT thread | A | C | H | L | R | W inch | Min bore | Min. Bore | ||||||||||

| inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | inch | mm | |||||||

| 1/8 | 1/8 | 1.82 | 46.2 | 0.91 | 23.1 | 0.72 | 18.3 | 0.66 | 16.8 | 0.34 | 8.6 | 5/16 | 0.09 | 0.09 | 2.3 | ||||

| 3/16 | 1/8 | 1.88 | 47.8 | 0.94 | 24.6 | 0.75 | 19.1 | 0.69 | 17.5 | 0.38 | 9.7 | 7/16 | 0.13 | 0.13 | 3.3 | ||||

| 1/4 | 1/8 | 2.03 | 51.6 | 1.02 | 25.9 | 0.78 | 19.8 | 0.72 | 18.3 | 0.38 | 9.7 | 7/16 | 0.19 | 0.19 | 4.8 | ||||

| 1/4 | 1/4 | 2.15 | 54.6 | 1.08 | 27.4 | 0.94 | 23.9 | 0.78 | 19.5 | 0.56 | 14.2 | 9/16 | 0.19 | 0.19 | 4.8 | ||||

| 5/16 | 1/8 | 2.21 | 56.1 | 1.10 | 27.9 | 0.81 | 20.6 | 0.81 | 20.6 | 0.38 | 9.7 | 9/16 | 0.19 | 0.19 | 4.8 | ||||

| 5/16 | 1/4 | 2.21 | 56.1 | 1.10 | 27.9 | 1.00 | 25.4 | 0.81 | 20.6 | 0.56 | 14.2 | 9/16 | 0.25 | 0.25 | 6.4 | ||||

| 3/8 | 1/4 | 2.27 | 57.7 | 1.13 | 28.9 | 1.00 | 25.4 | 0.84 | 21.3 | 0.56 | 14.2 | 9/16 | 0.28 | 0.28 | 7.1 | ||||

| 3/8 | 3/8 | 2.53 | 64.3 | 1.26 | 32.0 | 1.13 | 28.7 | 0.97 | 24.6 | 0.56 | 14.2 | 3/4 | 0.28 | 0.28 | 7.1 | ||||

| 1/2 | 3/8 | 2.71 | 68.8 | 1.35 | 34.3 | 1.13 | 28.7 | 0.97 | 24.6 | 0.56 | 14.2 | 3/4 | 0.41 | 0.41 | 10 | ||||

| 1/2 | 1/2 | 2.83 | 71.9 | 1.41 | 35.8 | 1.31 | 33.3 | 1.03 | 26.6 | 0.75 | 19.1 | 7/8 | 0.41 | 0.41 | 10 | ||||

| 5/8 | 1/2 | 2.89 | 73.4 | 1.44 | 36.6 | 1.34 | 34.0 | 1.08 | 26.9 | 0.75 | 19.1 | 7/8 | 0.50 | 0.5 | 13 | ||||

| 3/4 | 3/4 | 3.09 | 78.5 | 1.54 | 39.1 | 1.50 | 38.1 | 1.16 | 29.5 | 0.75 | 19.1 | 1.1/16 | 0.63 | 0.63 | 16 | ||||

| 7/8 | 3/4 | 3.33 | 84.6 | 1.66 | 42.2 | 1.50 | 38.1 | 1.28 | 32.5 | 0.75 | 19.1 | 1.5/16 | 0.72 | 0.72 | 18 | ||||

| 1 | 3/4 | 3.56 | 90.4 | 1.78 | 45.2 | 1.66 | 42.2 | 1.31 | 33.3 | 0.75 | 19.1 | 1.5/16 | 0.72 | 0.72 | 18 | ||||

| 1 | 1 | 3.56 | 90.4 | 1.78 | 45.2 | 1.84 | 46.7 | 1.31 | 33.3 | 0.94 | 23.9 | 1.5/16 | 0.88 | 0.88 | 22 | ||||

| Metric Tubing | |||||||||||||||||||

| Tube O.D mm | NPT thread | A | C | H | L | R | W inch | Min bore mm | |||||||||||

| mm | mm | mm | mm | mm | |||||||||||||||

| 6 | 1/8 | 51.6 | 25.8 | 19.8 | 18.3 | 9.7 | 7/16 | 4.8 | |||||||||||

| 6 | 1/4 | 54.6 | 27.3 | 23.8 | 19.8 | 14.2 | 9/16 | 4.8 | |||||||||||

| 8 | 1/8 | 56.2 | 28.1 | 20.6 | 20.6 | 9.7 | 9/16 | 4.8 | |||||||||||

| 8 | 1/4 | 56.2 | 28.1 | 25.4 | 20.6 | 14.2 | 9/16 | 6.4 | |||||||||||

| 10 | 1/4 | 66.0 | 33.0 | 28.6 | 25.4 | 14.2 | 3/4 | 7.9 | |||||||||||

| 10 | 3/8 | 66.0 | 33.0 | 28.6 | 25.4 | 14.2 | 3/4 | 7.9 | |||||||||||

| 12 | 1/4 | 69.4 | 34.7 | 28.6 | 24.6 | 14.2 | 3/4 | 9.5 | |||||||||||

| 12 | 3/8 | 69.4 | 34.7 | 28.6 | 24.6 | 14.2 | 3/4 | 9.5 | |||||||||||

| 12 | 1/2 | 72.6 | 36.3 | 33.3 | 26.2 | 19.1 | 7/8 | 9.5 | |||||||||||

For any requirements related to Male Branch Tee, Click here :-

or

Export Destination of Male Branch Tee

SMSM India have exported Instrumentation Fittings to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.

Supplying Male Branch Tee to Following Domestic Cities

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Bhopal, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Vijayawada, Madurai, Varanasi, Meerut, Faridabad, Rajkot, Jamshedpur, Srinagar, Jabalpur, Asansol, Vasai Virar City, Allahabad, Dhanbad, Aurangabad, Amritsar, Jodhpur, Ranchi, Raipur, Kollam, Gwalior, Durg-Bhilainagar, Chandigarh, Tiruchirappalli, Kota

Industries where we supply Male Branch Tee

Chemicals, Petrochemicals, Oil & Natural Gas Organization, Fats, Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps, Automation, Paints, Steel Industries, etc.